Duct Sealing Key To Preventing Cold Blow & Discomfort With Heat Pumps

How Aeroseal’s air sealing of duct work prevents one of the most common heat pump complaints

Maintaining a constant temperature in the home during the colder months has been an ongoing struggle for this Xenia, Ohio family since moving in back in 2018. So much a struggle that they installed a wood-burning stove to supplement their 2-heat pump system during the coldest months of the year.

When the thermostat would be set at 70°F (21°C), register air temperatures would range anywhere from 85°F to as low as 67°F at the far ends of the house, meaning the heat pumps were actually cooling certain rooms of the home.

This problem could be caused by a variety of things, but mainly due to leaky ducts. The conditioned air moving through the ductwork is lost through poor connections and by the time it reaches the register, the conditioned air is lost.

After sealing, the system leakage and register air temperatures were measured again. System leakage was cut by over 88%, from an average of 245CFM to 27CFM. More impressively, the average air temperature from the registers increased by 5°, completely resolving the cold air coming from the farthest registers.

This non-destructive process was able to eliminate the cold air coming from the registers and reduced leakage to only 2% without having to redo the ductwork or changing out the heat pumps.

Project Overview

BUILDING

Two-story Tudor-style home with 2 heat pumps

LOCATION

Xenia, OH

AEROSEAL CONTRACTOR

Aeroseal Training Staff

GOAL

Normalize temperature throughout house and increase register air temperature

BEFORE AEROSEAL

Average Register Temperature: 79ºF (26°C)

Average CFM Loss – 245 CFM or 20% of system capacity

AFTER AEROSEAL

Average Register Temperature: 84°F (29ºC); a improvement of 5°

Average CFM Loss – 27 CFM or 2% of capacity; a 88% decrease

1 CFM = Size of a Basketball

“Knowing that heat pumps don’t really provide warm heat, when we bought the house we were concerned about how high our energy bills could be in the winter due to having two electric heat pump systems. Not only that, the furthest rooms from the furnace – which happen to be the family room and living room where we spend a majority of our time together as a family – were always cold because of the small amount of airflow coming out of the registers. After Aeroseal, not only can you feel a difference in the amount of air coming out of the registers, but those cold rooms are now more comfortable, not to mention the furnace is kicking off a lot sooner than it was before having Aeroseal work done, which we’ll hopefully see the monetary impact of that on our future energy bills.”

Homeowner

How Aeroseal Works

STEP 1

Prep & Test

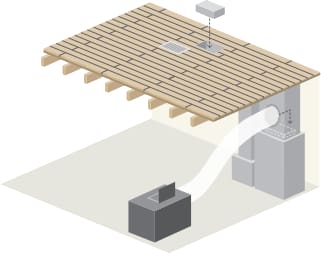

Registers, air conditioning indoor coil, fan, and furnace are temporarily blocked with foam plugs to force air in the duct work to escape through any leaks and prevent sealant particles from entering parts of the HVAC system. Once the system is prepped, the Aeroseal machine is connected to the duct work using lay flat tubing. A small access hole is cut into the supply or return, and a temporary collar is attached. The Aeroseal system runs a pretest that pressurizes the duct system and detects the exact amount of duct leakage in the duct system.

STEP 2

Seal & Measure

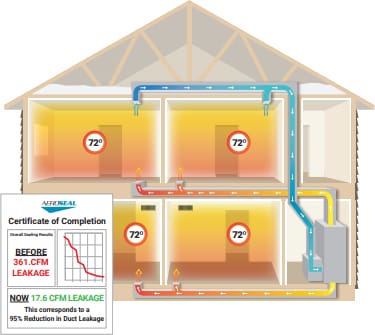

The patented aerosol sealant is injected as a mist into the ductwork. Holes and cracks in the duct system are found by the pressurization. Aerosol particles collect on the edges of holes and cracks in the ductwork to seal them from the inside. Results are shown in real-time on the computer.

STEP 3

Review Results

After the sealing completes, a computer-generated report summarizes the duct leakage reduction, providing a verifiable certificate of the success of the Aeroseal application.